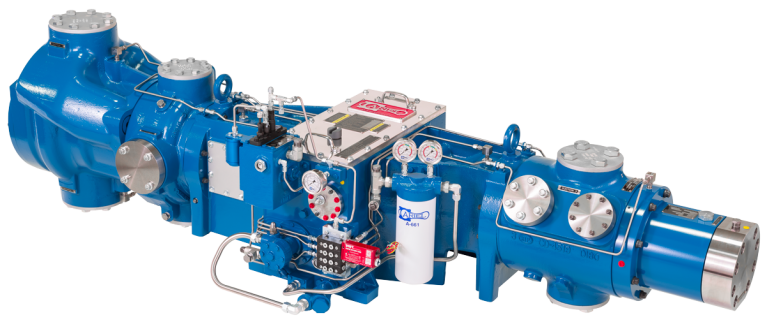

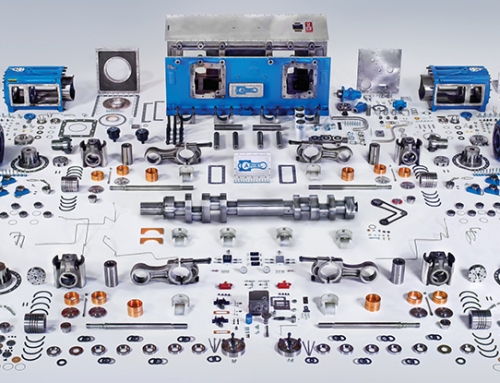

Ariel compressors are low maintenance, but there are times when a problem can occur and will require some parts to be replaced. To ensure a longer service life, it is recommended that you replace them with authentic Ariel compressor parts supplied by reputable providers and trusted distributors like Ironline Compression. Ariel parts are carefully designed, engineered, and manufactured to ensure maximum reliability in every application in the field. Use this guide to make sure that you are buying genuine parts for your Ariel compressor, whether for reconfigurations or maintenance, as well as for overhauls:

- Things to keep in mind – You can identify authentic Ariel compressor parts in many ways, starting with the surface finish, which must be free of imperfections like rough edges and burrs. Look for the anti-corrosive signature blue paint, which must be applied consistently. Ariel cylinder bores and piston rods go through ion-nitride treatment for extensive service life. Make sure the piston rods have rolled, necked down threads.

- Look for the Ariel logo – Genuine Ariel compressor parts will have the logo etched on them, particularly on valves. Part numbers are stamped on the outer edges of the valve’s seat and guard. Ariel valves come in many combinations of concentric and actuated valve, ring, and plate designs, and they are paired with X Blend superior metallic plates, non-metallic sealing elements, and top notch springs.

- Make sure the packing case is stamped – Authentic packing cases by Ariel have a clear stamp on the packing flange face. Look for the logo and the part number.

- Things to look for in the BTUU ring – BTUU uncut ring technology is designed for longevity and reliability as it operates with lower fugitive emissions. It uses Ariel’s necked-down piston rode design, so it uncut ring sets can be installed. These Ariel compressor parts have replaced radial cut back-up rings, which were the previous standard.

Leave A Comment Cancel reply