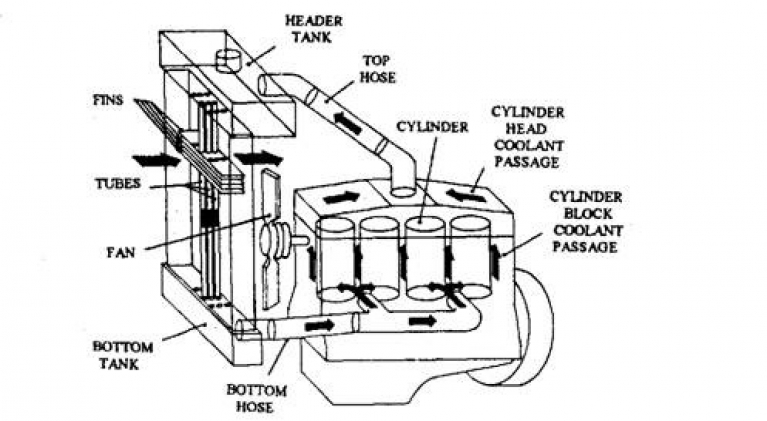

Thermo-Syphon is the process of passive heat exchange that occurs under the conditions of natural convection to make fluid circulate without a mechanical pump. This system is typically used in circulating volatile gases and liquids in cooling and heating applications, like water heaters, heat pumps, furnaces, and boilers. The circulation can be open-loop where the substance in the holding tank passes through a single direction via the heated transfer tube, which is mounted beneath the tank to the distribution point. Or, it can be a closed-loop vertical circuit, which allows return to an original container. In any case, even with an Ajax gas compressor, the purpose of thermo-syphoning is to transfer gas or liquid, while avoiding the complexity and cost of a conventional pump.

Ajax is among the leading brands when it comes to compressors and engines known for their up-to-date and innovative solutions. Its integral engine compressors provide gas compression services using built-in reciprocating engines. This way, an Ajax gas compressor is typically compact, easier to install, and energy efficient. Ironline Compressions carries a range of their products, which are known for their continuous service, adaptability, and dependable operation. The compressor’s design uses a two-cycle system, so it does not have troublesome valves, rocker arms, push rods, cams, and tappers. The absence of those parts help reduces maintenance costs, while increasing reliability. Water circulation is dependent on the temperature of the engine, so it should be greater under higher temperatures.

Ironline Compressions carries a range of Ajax gas compressor systems that are low-maintenance and designed with the Thermo-Syphon cooling system to prolong engine life and extend performance. You might find these products capable of performing, even when exposed to the toughest conditions in the field or under continuous loads in an oil field. Engine temperature is controllable, and noise is minimized as it goes through a water jacket.

Leave A Comment