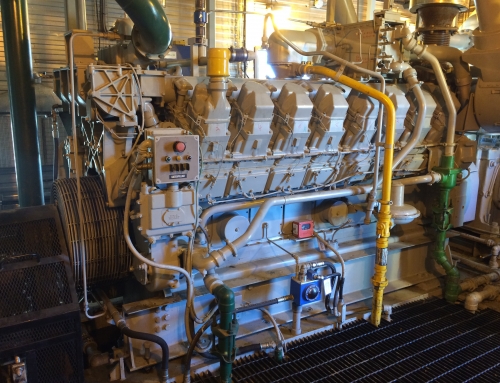

Gas compressors are essential power sources for most of the businesses, and they have different types of applications for use. Natural gas compressor parts works a long way and hard depending upon the environment, so it’s imperative to keep the internal workings of the air system maintained well to benefit the production of business and profits. Each part has a particular function and if they are not well-maintained, it can affect the energy consumption, air supply, and service frequency.

Depending upon the application, you can choose the Ironline compressor either in the industrial solution or piston design called the rotary screw design. All of them have a different method of getting the same result: create compressed gas.

Know the gas compressor parts

The list of compressor parts includes parts from the piston models which will help you to get more familiar with gas compressor function:

- Bearings

Industrial class bearings make sure along with operating life for the operations which are demanding. These bearings will offer you peace of mind as the compressor works at high revolutions with more pressure.

- Actuators

This creates linear or rotary movement and it is something that outputs the compressed gas to the processes or tools that make use of pressurized gas for power use. Any type of leak or any other deficiency in the movement of air taking place in the actuator will lead to air force decrease coming out. Little particles in the atmosphere will lead to a blockage in the actuator, along with various other parts of the gas compressor.

- Bumpers

The bumpers of valve surround it for the added protection from the accidental damage. Replace the small part of the shield when it’s necessary to get rid of more expensive valves replacement.

- Belts

This needs to be considered every 40-45 hours for operation and wear. Working to drive the compressor operation, it is essential for the belts to be of the best and high quality and it needs to get fit properly.

Bottom line

Avoid additional expenses from improper maintenance checks. The frequency of the repairs can be decreased by using the genuine natural gas compressor parts from Ironline Compression.

Leave A Comment