As a Platinum Packager for Waukesha engines, Ironline offers Waukesha emission reduction upgrade packages.

Emission reduction programs are available for producers to recover investment in engine retrofits that reduce Green House Gas (GHG).

These solutions consider the total GHG footprint of the engine, and the reduction results are not limited to fuel savings.

Ironline Compression works with companies upgrading their Natural Gas engines into ultra-efficient engines, that will reduce GHG and meet NOx emissions levels.

The Challenge is to find a solution that reduces both NOx and GHG.

Features:

- VHP Series Five engines come standard with ESM*2, INNIO’s next-generation engine controller. With its full color customer interface panel, the ESM2 allows you to see all engine parameters and trend data, view manuals, and walk through troubleshooting steps—all without the need for a laptop computer.

- INNIO’s emPactemission control system is the option of choice for reducing emissions below 0.15 g/bhp-hrof Nox

- emPactoptimizes the interactions among the Series Five engine, AFR2 air/fuel ratio control, and the INNIO-supplied three-way (NSCR) catalyst to maintain emissions compliance even as engine speed, load, fuel, and environmental conditions change.

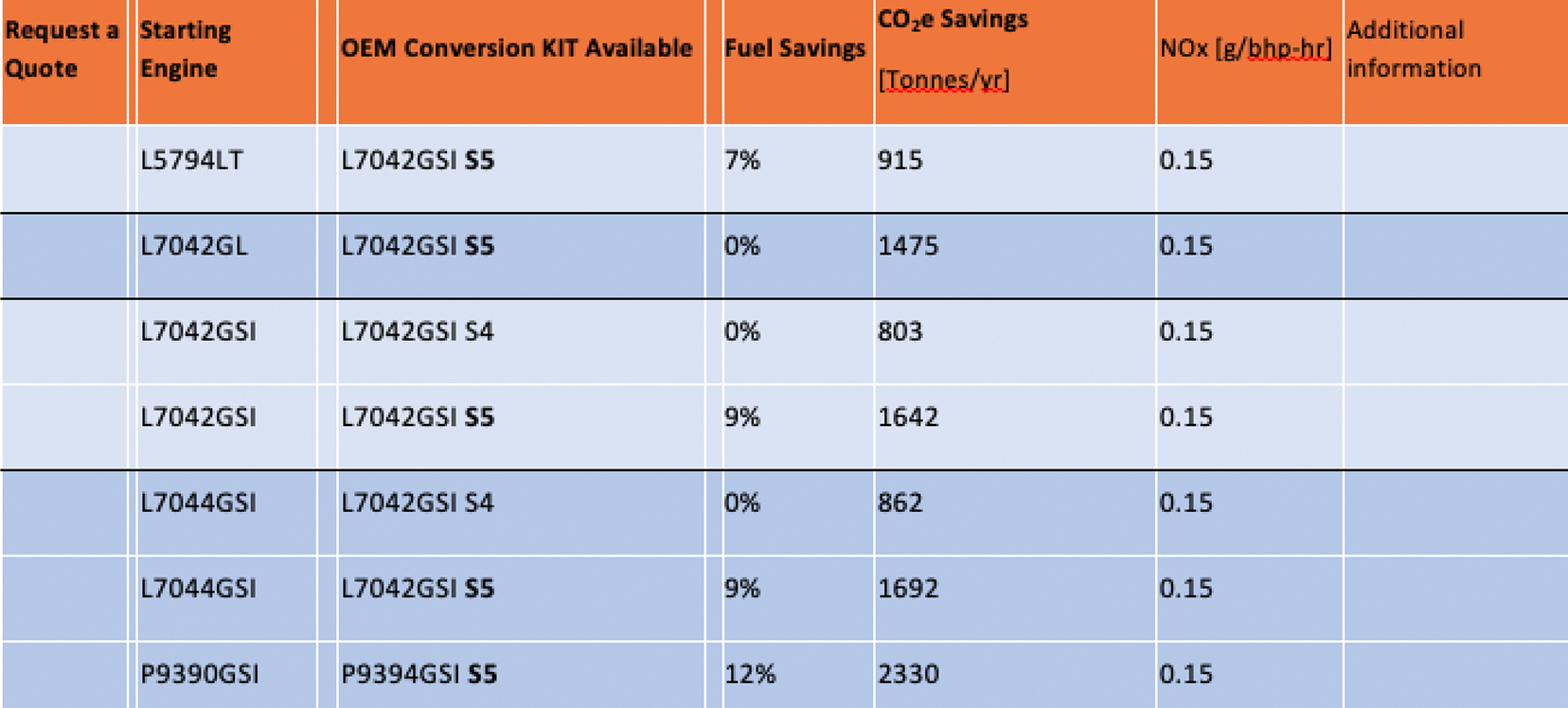

- See Tablebelow for engine conversions available and potential GHG reduction

Models available to upgrade:

- L5794LT

- L7042GL

- L7042GSI

- L7042GSI “lean”

- P9390GL/GSI

- L7044GSI

Waukesha VHP Series Five

The Waukesha VHP Series Five rich-burn engines combine today´s advanced technology with 50 years of experience on the VHP platform. Available as a 1900 hp L7044GSI S5 and a 1500 hp L7042GSI S5, these Series Five reciprocating gas engines deliver up to 13% more power, better fuel flexibility, as much as 10% lower fuel consumption, up to 20% lower lifecycle costs, and over 30% longer service intervals.