Gas Compressors And Maintaining Safety

Regardless of industry, anytime heavy equipment is used, companies must take steps to ensure the safety of workers and the surrounding residents and environment. Quality gas compressors can be safe, effective tools, especially when organizations and staffers follow safety tips such as the ones below.

Monitoring and Maintenance is Key

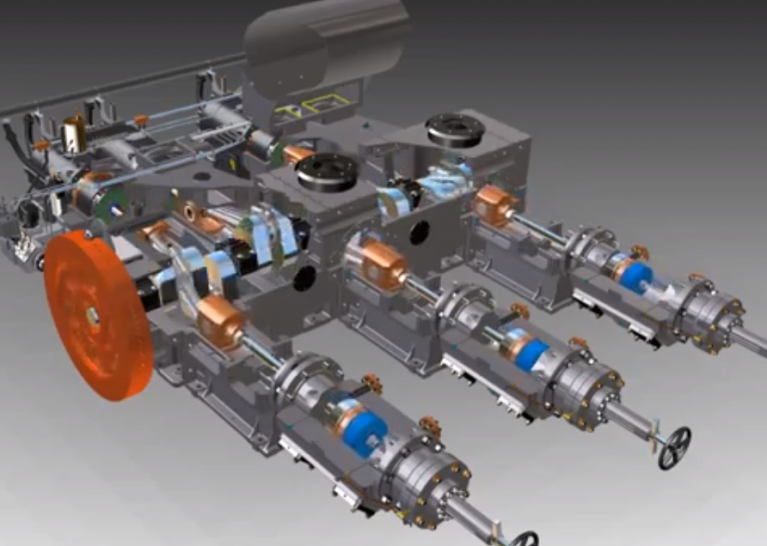

Appropriate maintenance of any equipment on a job site or station is critical to ongoing safety, and gas compressors are no exception. When you rent a compressor, begin by inspecting the equipment you receive. If you notice anything that seems odd, out of place, or in disrepair, notify the rental company immediately and don’t put the machine into production until items have been addressed or deemed safe. Once a rented gas compressor is in place, monitor it regularly. Create processes for regular visual reviews of the machine, and consider testing the operational efficiency of the machine at certain intervals to ensure everything continues to work well.

Gas Compressor Noise is Regulated

When you rent any type of machinery, make sure you understand all the regulations that are involved. These types of compressors come with numerous safety and environmental regulations, and following those rules can make everyone safer. For example, the noise output may be regulated by the FERC. In some cases, a gas compressor station is required to produce sound at lower than 55 decibels, which is only slightly more than what the average dishwasher in a residential kitchen might produce. If your compressor is making more noise, you may be out of regulation and it may be a sign that something is wrong.

Staff Must Be Property Trained

Finally, any staff working with rented equipment, including compressors, should always be well trained on the machines. Take time to train staff and create policies that manage who can work with or on rented compressors.

Leave A Comment