Why do people from several industrial circles prefer exchange engine services over buying a new engine or engine part?

Every time an engine or a compressor decides to call it a day, it ends with several workers redundant, supply lines disrupted and manufacturing stopped. The result is a severe loss of energy, time, money and much more.

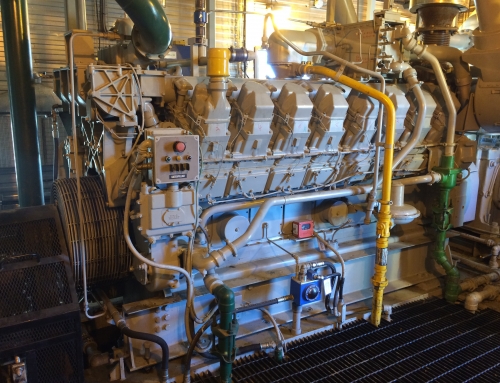

When engines are called lifelines of an industry, it is only natural that they stop the whole process when they fail to deliver what they had promised to do. That is why the use of exchange engines are preferred to ensure the downtime and waste of man-hours can be avoided.

Also, with the ‘exchange engines’, the cost of replacing a particular part, especially an expensive one is minimal. As soon as a problem is detected, the parts or the engine can be replaced to keep it running. When it comes to buying a new and original part, the cost may sometimes even exceed the engine itself.

The delay in delivery of these new engine parts is also an issue. The new engine parts are manufactured at the facility, and takes time to reach the users after a requisition has been made. The used engine parts come with a guarantee of reaching the facility to avoid downtime. The suppliers of exchange engine parts and services, such as Ironline compression have with them several revamped and remade engine parts always ready and available.

This makes it easier to find the perfect engine part without any delay. Time, energy and money, all can be saved by buying the suitable exchange engine parts from Ironline compressions. They come with a warranty of purchase and therefore, are completely safe to use. The suppliers are there to resolve any issues arising out of these exchange engine parts.

Leave A Comment